Master CNC Programming with Inventor CAM

Unlock the Power of Precision with Inventor CAM– Learn Advanced CNC Programming Today

Course Highlights: Inventor CAM Course at The CADD

SolidCAM is a powerful CAM solution integrated directly inside SolidWorks, ideal for milling, turning, and mill-turn operations. Our course helps you become industry-ready with real part programming and simulations.

Integrated CAM with SolidWorks

Learn CAM operations within the familiar SolidWorks interface — no switching software.

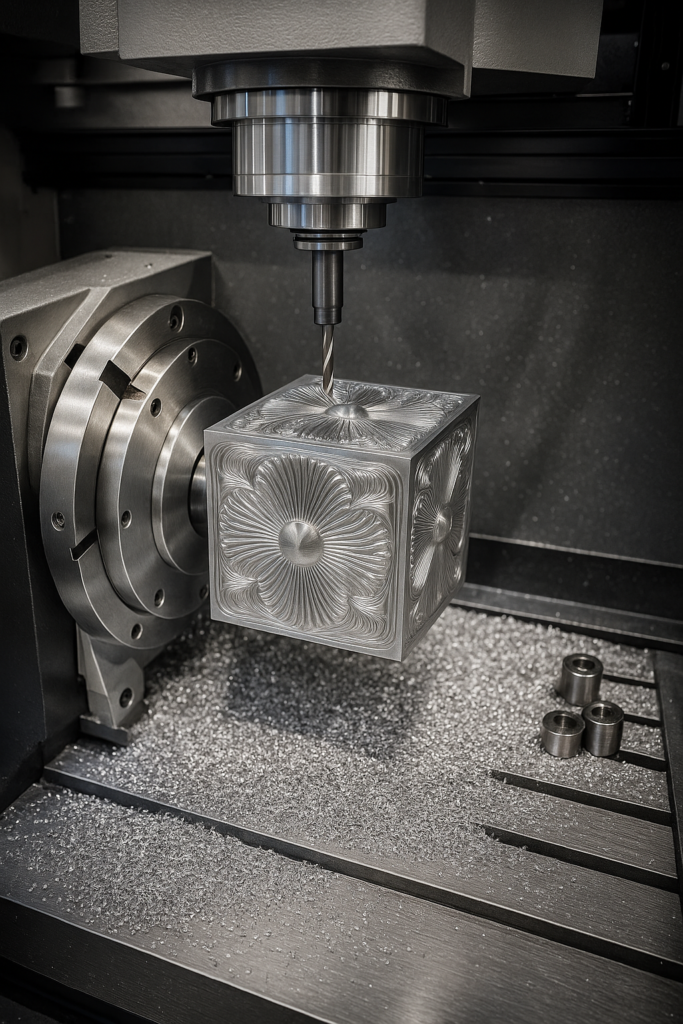

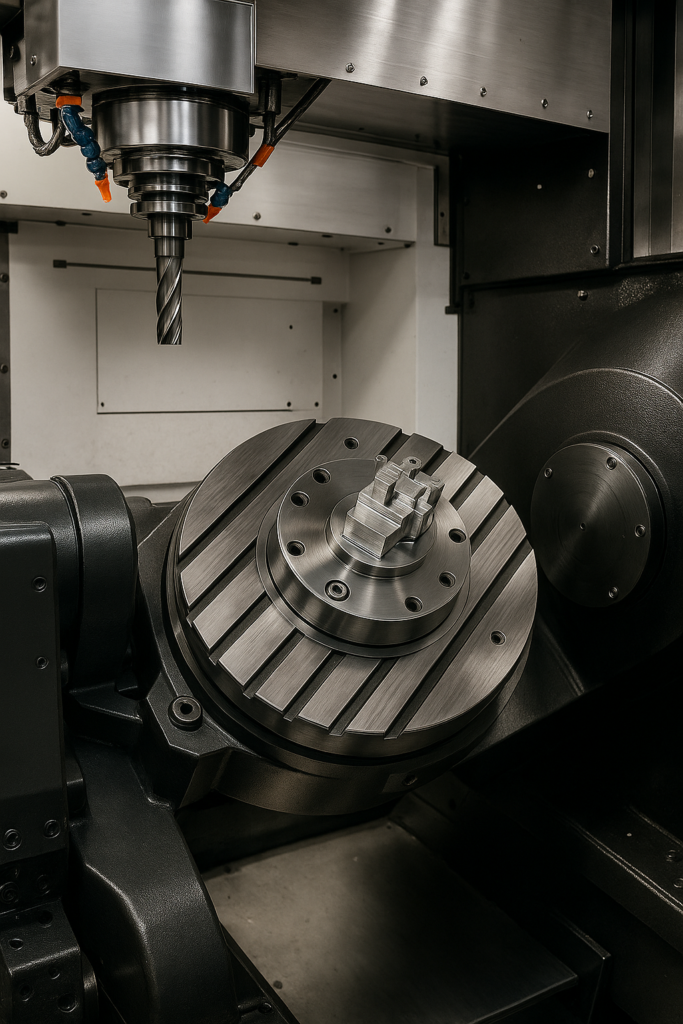

2.5D to 5-Axis Machining

From simple drilling to complex multi-axis toolpaths, we cover it all.

Live Project-Based Learning

Gain experience with real industrial components and part programming.

Post Processor Setup & G-Code

Understand how to generate and edit NC programs for different CNC machines.

Simulation & Collision Detection

Learn to simulate toolpaths with full machine preview to avoid crashes.

Certificate on Completion

Get certified by The CADD with a unique ID for digital verification.

Course Modules for Inventor CAM Training Program

Module 1: Introduction to Inventor CAM

- Overview of CAM principles, interface, and integration inside SolidWorks. Understand the workflow from CAD model to CNC program.

Module 2: SolidWorks Part Setup for CAM

- Learn how to prepare and import SolidWorks parts for CAM operations, including fixing geometry issues and defining machining faces.

Module 3: Coordinate System Definition

Setup of Machine Coordinate System (MCS), defining zero points and part orientation — a key step before toolpath creation.

Module 4: 2.5D Milling (Face, Pocket, Profile)

- Learn basic milling operations like facing, pocketing, contouring, and slotting. Ideal for flat parts and plate machining.

Module 5: Finish Toolpath Generation

- Generate precision finishing toolpaths for accurate surface quality.

Module 6: Drilling & Tapping

- Create toolpaths for drilling holes, tapping threads, and counterboring. Includes hole recognition and pattern creation.

Module 7: iMachining Technology

Exclusive to SolidCAM, iMachining uses advanced algorithms to reduce cycle time and tool wear. Learn both 2D and 3D iMachining.

Module 8: 3D Milling

- Handle curved surfaces and complex geometry using HSR/HSR (High-Speed Roughing/Finishing) and 3D contour strategies.

Module 9: Multi-Surface Operations

- Machine parts with varying surface angles, apply adaptive roughing and constant Z finishing techniques for molds and dies.

Module 10: Tool Library & Selection

Learn how to manage a tool library, define tools, and select appropriate tools based on material, depth, and speed requirements.

Module 11: Post Processor & G-Code Generation

Generate NC code compatible with different CNC controllers. Learn how post processors work and how to customize them.

Module 12: Simulation & Verification

- Simulate complete toolpaths with collision detection and material removal preview — essential for avoiding machine crashes.

Module 13: Basic Turning

- Introduction to CNC turning operations — including roughing, finishing, threading, and groove creation.

Module 14: Practice with Live Parts

Apply everything you’ve learned on real industrial parts. Convert CAD models to CAM, simulate, generate G-code, and understand practical workflow.

Certification

Get a certificate from The CADD with a unique ID for online verification.

Course Duration

Learn at Your Pace

Our Inventor CAM course is thoughtfully designed to fit into your schedule — whether you’re a student or a working professional.

Duration: 1.5 Months

Schedule: 3 Days a Week

Timing: 1.5 Hours Daily

But we don’t just follow the clock — we follow your clarity.

Our commitment is simple — we’ll continue to guide you until you’re truly confident.

That means even if the standard duration ends, you’ll still have access to doubt sessions and extra support until you master every essential concept.

At The CADD, learning isn’t limited by time — it’s driven by your success.